The importance in the optimization of processes in the industry

The main objective of optimizing the processes of any current factory or industrial plant to the maximum is to increase the efficiency of the company by perfecting its entire production cycle, making intelligent and profitable use of its resources. Perfecting your workflows, avoiding the duplication of tasks or making an analytical forecast of possible setbacks are just three of the many actions that encompasses this concept that is heard so much today in the business world:

More than one reason to optimize your industrial processes

– Reduce economic costs. When a detailed study is carried out to achieve the best implementation of systems for the correct optimization of processes in the industry, it is possible to identify with great accuracy the possible failures in the production chain that may currently be causing your company to lose money. By changing them, it is possible to improve the total profitability of the entire cycle of production, distribution and sale.

– They also optimize time management. The detection of parts of the process of little or no use serves to eliminate them completely without any undesirable consequences. On the contrary, readjusting the processes will allow your resources to focus directly on the efficient and productive tasks of your industrial plant.

– Prevent and avoid risks. If you design a good plan for the proper optimization of processes in the industry in the medium and long term, you will achieve a high level of standardization and formalization of the entire workflow. Thus, you will prevent your workers from continually having doubts about their tasks to be carried out or, also, you will achieve a rapid reduction in the rate of habitual errors, among many other benefits.

– They offer a fast and efficient global vision. The fact of making a good ‘map’ of the entire production chain of your services or products, will allow you or your specialized planning team to know when and how to integrate between the different phases or implement new processes.

– Improve efficiency. Excellent customer service is essential for the proper functioning of any industrial business organization, so the good optimization of industrial processes is also crucial to be able to perform your services within the deadlines agreed with the client or deliver your order on time.

– They get an immediate reaction to the resolution of incidents. Having good control and analysis of every phase of your production process will allow you not only to identify problems or management failures, but you will also be able to know in depth and in real time the reasons that have generated them. This privileged information will be very useful to give them a quick solution.

– Established quality and safety controls will be easily met. The rigorous monitoring and standardization of the different stages for the necessary optimization of processes in the industry, also helps to a great extent to perfectly comply with your own internal controls and those imposed by the competent public authority in security matters of workers and quality of products.

– Improve short-term results. It is the main reason, because they mean the growth and increase in your company income in the industrial sector. In a very short time, the profitability offered by the implementation and real execution of a good workflow optimization plan that lasts over time will allow you to gain positioning in the national and international market.

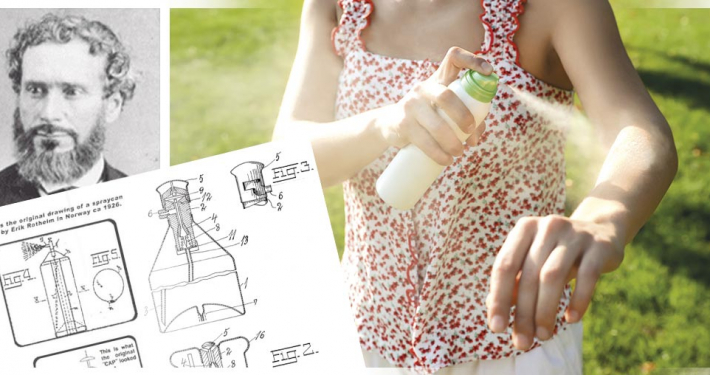

The optimization of processes in the pharmaceutical industry comes from the hand of GRIT

If you work in the pharmaceutical sector, you will like this ending. It is important that you get to know GRIT company if you have not already done so, for all the benefits that it will bring to your company in terms of optimizing resources in the industry. And it is that the company, specialized exclusively in the production, storage and distribution of liquefied gases and other similar mixtures dissolved in solvents, makes its revolutionary products for the synthesis of active pharmaceutical ingredients available to this very competitive industry that will help you save costs and produce much faster.

■ Communication Team